Sense Relay Manufacture

A total of 104 of these special double Siemens type relays had to be made plus a few spares. The original Siemens design was based on a single version but the only parts that are common to the BTM version are the armature and the very small contact assemblies. We recovered these items but had to make the rest ourselves. It is interesting to note that the British Tabulating Machine Company used this type of relay in their Punched Card equipment after the war. I wonder how they explained how this relay came to be developed?

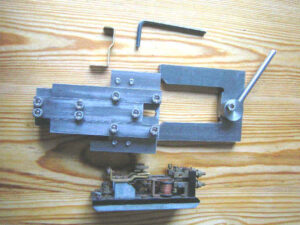

Below are a series of images showing a selection of the parts being made.

Above are the insulated bases. These were machined out of raw material and then drilled. The drilling jig can be seen on the right.

The 104 bases were also made from basic material. In this case, the outer holes had to be tapped. There was a strange deviation here. All other parts on the Bombe have American UNF or UNC threads. In the case of these relays B.A. threads were used; mainly 5 B.A.

Here we have the armature supports. 208 were required with each needing 3 threaded holes.

Above are assembled base assemblies. At this stage of construction, the drawings called for all the top surfaces to be flat. Therefore every assembly had to be mounted in a mill and the tops of the items machined true.

Above, at the bottom of the picture can be seen an original W.W.II relay. This was somehow ‘liberated’ during WWII and then passed to us recently. Above the armature can be seen a brass adjusting screw support. 208 of these were required and folding brass strip to the required shape is not an easy task. Therefore Mike Hillyard made a special jig as can be seen above. The following images show this in use and the finished items.