PLATES

The full set of plates were manufactured by Nortel Networks at Harlow on their very advanced Computer Controlled Punching Machine. They were produced from files created using AutoCad. These were processed and forwarded to Nortel who did the rest.

On their return, the plates were drilled, tapped, countersunk and spring posts etc. fitted. This was carried out by a team of volunteers operating out of Harlow. The majority of these Ladies and Gentlemen are ex STC or Nortel employees.

The main parts of the Bombe drive and carry mechanisms operate between and behind two sets of these plates. These are mounted on the front and rear of the main horizontal bars, 1 3/8″ apart. There are 36 small and 3 large plates towards the front of the machine and a similar matching set at the rear.

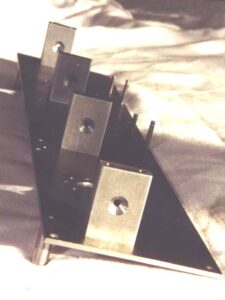

Above are a selection of small front plates with the drilling, countersinking and thread tapping completed. The front panel mounting pillars have been riveted in place. The upper group show the rear side; the lower, the front.

In this view, spring pillars have also been riveted in place on the rear of the plate and four spacer blocks have been screwed in place. When fitted this would be a view from the top of the machine

This is another rear view; more or less the right way up.

Above is a close-up view showing where a main drum spindle bush is to be fitted. The machined groove is to allow oil from the lubrication system to enter the small hole in the bush shown in ‘Letchworth Enigmas’.

Go to Letchworth Enigmas – Mechanical