LUBRICATION

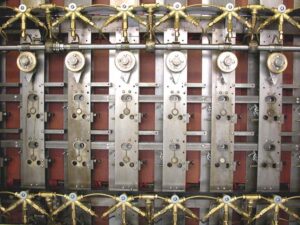

The lubrication system on the British Bombe is quite comprehensive. It feeds 177 places through 5/32″ OD brass pipe and a large number of junctions to precision metering valves. Even then it only reaches places that are inaccessible. Some bearings still have to be lubricated with an old fashioned hand oil can.

We had no detailed drawings of all the junctions and unions involved; just original Tecalemit part numbers. Tecalemit no longer deals in chassis lubrication systems and some years ago they sold this part of the business to a rival. However, we were very lucky in that the Sales Manager of the new company was an ex-employee of Tecalemit. He was extremely helpful but pointed out that whilst he remembered the parts by the numbers we gave him they had not made them for decades except that their metering valves under new part numbers were virtually identical.

He promised to look into their archive and after a while, he came back with dimensioned sketches of all the items we required. He also supplied the 171+ metering valves at a very acceptable price, for which we are extremely grateful.

With no supply possibility, we had no choice but to make our own parts. The first thing we needed was brass castings and before that casting patterns. Luckily a brass foundry near to where I live was able to help. They advised us on making the pattern which Steve Brooke made onto a board using dowel and panel pins with filler material to ’round’ the joints.

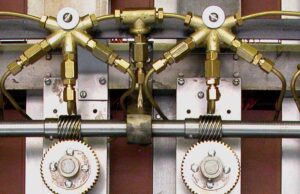

The next step was machining. The critical issue was that all the drillings had to meet up at the same point. Mike Hillyard, therefore, produced a special jig onto which the casting was mounted.

This allowed the casting to be rotated around the ‘focus’ and with indents to hold the position during machining. We also had to make special stepped drills followed by taps to thread the holes.

Standard couplings, olives and pipe were purchased and Tony Walden completed the difficult job of routing all the pipework according to original drawings and photographs.

Rear view of machine showing the full lubrication system installed

CORRECT LUBRICATION PUMP REQUIRED